How to Avoid 83% of OEM Mistakes | Choosing Your Perfect Sportswear Supplier Partner

A 2023 Global Textile Sourcing Report reveals a harsh truth: 68% of emerging brands face delayed shipments in their first OEM partnership, while 42% lose over $15,000 due to fake supplier certifications. For buyers like Daman, a 26-year-old US procurement manager, these risks threaten brand reputation and cash flow.

But what if you could eliminate 83% of these mistakes?

1. The Certification Trap: How to Spot Fake OEM/ODM Suppliers

The Problem: Over 60% of "certified" suppliers falsify ISO9001 or BSCI documentation (Source: SGS Audit Data).

The Fix:

Demand LIVE Verification: Insist on video factory tours to cross-check certifications against actual workshops.

Ask for Transaction Histories: Legitimate manufacturers openly share client references and export records.

Caption: Our 5 production lines in Guangzhou– verified via real-time video audits for Daman’s order.

2. Production Lines ≠ Reliability: The Math Behind On-Time Delivery

Key Metrics for Small Brands:

Daily Output: 5 lines = 8,000+ units/day (e.g., basketball jerseys)

Lead Time: 25-30 days for 5,000+ orders (vs. industry average 45 days)

Rush Order Capacity: 15% production buffer for urgent requests

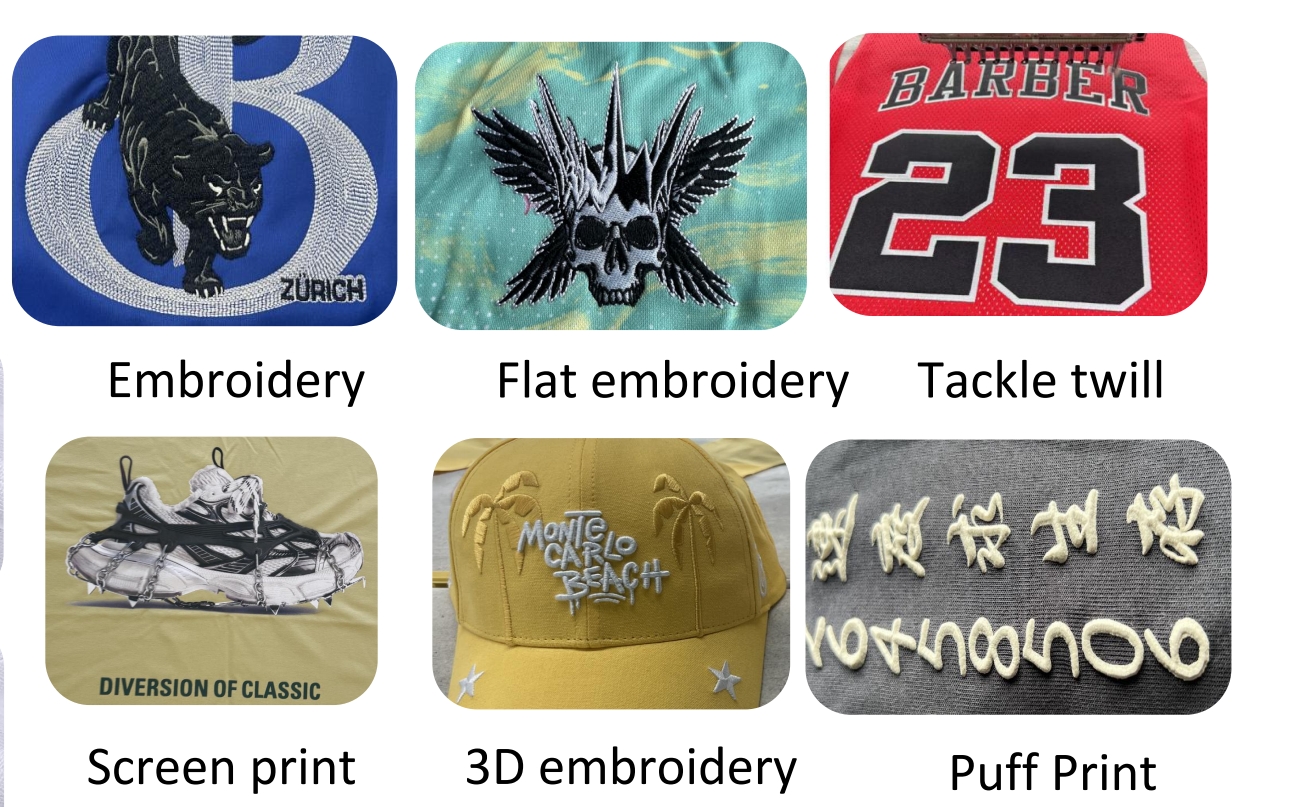

3. Custom Sportswear Design: Beyond "Logo Slapping" Services

True One-Stop Customization Includes:

150+ Fabric Options (moisture-wicking, recycled polyester, etc.)

Small-Batch Trials (10 units minimum)

Your Turn to Eliminate OEM Risks

Claim Your Free Supplier Toolkit Now:

✅ Instant Quote: Upload designs for a <24hr response

✅ Video Factory Tour: Live walkthroughs in English

✅ First-Order Protection: Free DHL-delay insurance